Page 4 - High Performance End Mills - Catalog 430

P. 4

MILLING TOOLS PORTFOLIO

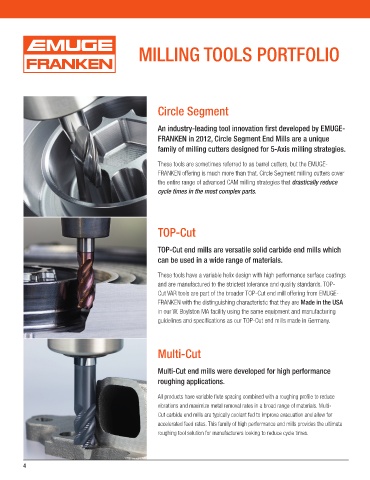

Circle Segment

An industry-leading tool innovation first developed by EMUGE-

FRANKEN in 2012, Circle Segment End Mills are a unique

family of milling cutters designed for 5-Axis milling strategies.

These tools are sometimes referred to as barrel cutters, but the EMUGE-

FRANKEN offering is much more than that. Circle Segment milling cutters cover

the entire range of advanced CAM milling strategies that drastically reduce

cycle times in the most complex parts.

TOP-Cut

TOP-Cut end mills are versatile solid carbide end mills which

can be used in a wide range of materials.

These tools have a variable helix design with high performance surface coatings

and are manufactured to the strictest tolerance and quality standards. TOP-

Cut VAR tools are part of the broader TOP-Cut end mill offering from EMUGE-

FRANKEN with the distinguishing characteristic that they are Made in the USA

in our W. Boylston MA facility using the same equipment and manufacturing

guidelines and specifications as our TOP-Cut end mills made in Germany.

Multi-Cut

Multi-Cut end mills were developed for high performance

roughing applications.

All products have variable flute spacing combined with a roughing profile to reduce

vibrations and maximize metal removal rates in a broad range of materials. Multi-

Cut carbide end mills are typically coolant fed to improve evacuation and allow for

accelerated feed rates. This family of high performance end mills provides the ultimate

roughing tool solution for manufacturers looking to reduce cycle times.