Page 74 - High Performance End Mills - Catalog 430

P. 74

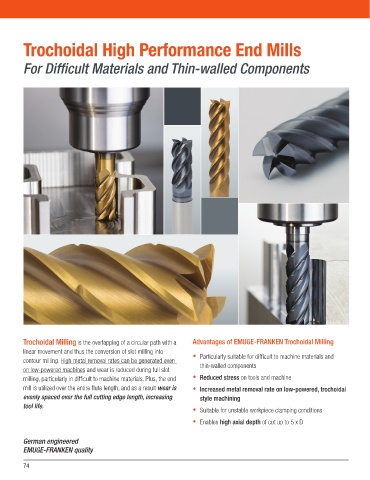

For Difficult Materials and Thin-walled Components

Trochoidal Milling is the overlapping of a circular path with a Advantages of EMUGE-FRANKEN Trochoidal Milling

linear movement and thus the conversion of slot milling into

contour milling. High metal removal rates can be generated even Particularly suitable for difficult to machine materials and

on low-powered machines and wear is reduced during full slot thin-walled components

milling, particularly in difficult to machine materials. Plus, the end Reduced stress on tools and machine

mill is utilized over the entire flute length, and as a result wear is Increased metal removal rate on low-powered, trochoidal

evenly spaced over the full cutting edge length, increasing style machining

tool life.

Suitable for unstable workpiece clamping conditions

Enables high axial depth of cut up to 5 x D

German engineered

EMUGE-FRANKEN quality