Page 75 - High Performance End Mills - Catalog 430

P. 75

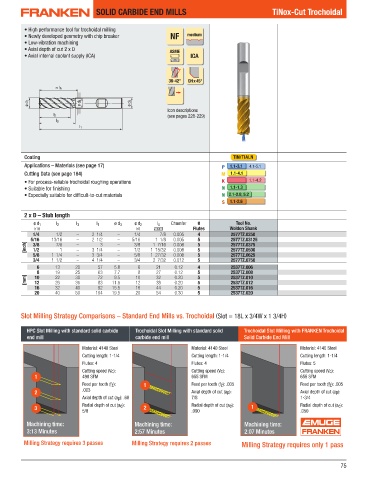

Coating

Applications – Materials (see page 17)

Cutting Data (see page 184)

l A

1/2 – 2 1/4 – 1/4 7/8 0.005

13/16 – 2 1/2 – 5/16 1 1/8 0.005

7/8 – 3 – 3/8 1 7/16 0.008

1 – 3 1/4 – 1/2 1 15/32 0.008

1 1/4 – 3 3/4 – 5/8 1 27/32 0.008

1 1/2 – 4 1/4 – 3/4 2 7/32 0.012

13 20 57 5.8 6 21 0.12

19 25 63 7.7 8 27 0.12

22 30 72 9.5 10 32 0.20

26 35 83 11.5 12 38 0.20

32 40 92 15.5 16 44 0.20

40 50 104 19.5 20 54 0.30

Slot Milling Strategy Comparisons – Standard End Mills vs. Trochoidal

HPC Slot Milling with standard solid carbide Trochoidal Slot Milling with standard solid Trochoidal Slot Milling with FRANKEN Trochoidal

end mill carbide end mill Solid Carbide End Mill

Machining time: Machining time: Machining time:

3:13 Minutes 2:57 Minutes 2:07 Minutes

Milling Strategy requires 3 passes Milling Strategy requires 2 passes Milling Strategy requires only 1 pass