Page 80 - High Performance End Mills - Catalog 430

P. 80

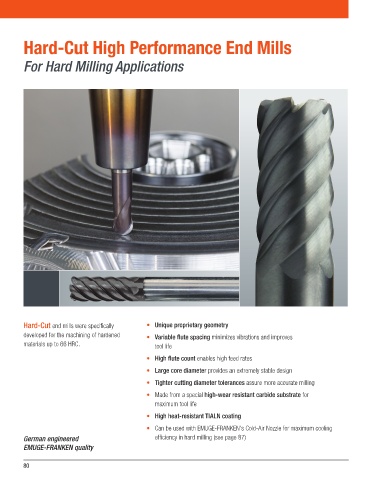

For Hard Milling Applications

Hard-Cut end mills were specifically Unique proprietary geometry

developed for the machining of hardened Variable flute spacing minimizes vibrations and improves

materials up to 66 HRC. tool life

High flute count enables high feed rates

Large core diameter provides an extremely stable design

Tighter cutting diameter tolerances assure more accurate milling

Made from a special high-wear resistant carbide substrate for

maximum tool life

High heat-resistant TIALN coating

Can be used with EMUGE-FRANKEN’s Cold-Air Nozzle for maximum cooling

German engineered efficiency in hard milling (see page 87)

EMUGE-FRANKEN quality