Page 62 - High Performance End Mills - Catalog 430

P. 62

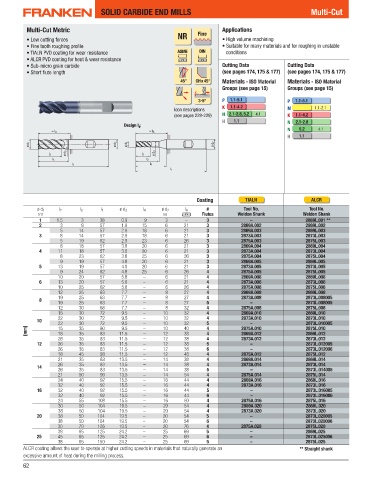

ø d 1 l 2 l 3 l 1 ø d 3 l 4 ø d 2 l A

h11 h6

1.5 3 38 0.9 9 3 –

3 8 57 1.9 15 6 21

5 14 57 2.9 18 6 21

8 14 57 2.9 18 6 21

5 19 62 2.9 23 6 26

8 18 57 3.8 20 6 21

11 18 57 3.8 20 6 21

8 23 62 3.8 25 6 26

9 19 57 4.8 20 6 21

13 19 57 4.8 20 6 21

9 24 62 4.8 25 6 26

10 20 57 5.8 – 6 21

13 20 57 5.8 – 6 21

10 25 62 5.8 – 6 26

12 25 63 7.7 – 8 27

19 25 63 7.7 – 8 27

19 25 63 7.7 – 8 27

12 30 68 7.7 – 8 32

15 30 72 9.5 – 10 32

22 30 72 9.5 – 10 32

22 30 72 9.5 – 10 32

15 35 80 9.5 – 10 40

18 35 83 11.5 – 12 38

26 35 83 11.5 – 12 38

26 35 83 11.5 – 12 38

26 35 83 11.5 – 12 38

18 45 93 11.5 – 12 48

21 35 83 13.5 – 14 38

26 35 83 13.5 – 14 38

26 35 83 13.5 – 14 38

21 50 99 13.5 – 14 54

24 40 92 15.5 – 16 44

32 40 92 15.5 – 16 44

32 40 92 15.5 – 16 44

32 40 92 15.5 – 16 44

24 55 108 15.5 – 16 60

30 50 104 19.5 – 20 54

38 50 104 19.5 – 20 54

38 50 104 19.5 – 20 54

38 50 104 19.5 – 20 54

30 70 126 19.5 – 20 76

38 65 125 24.2 – 25 69

45 65 125 24.2 – 25 69

38 65 150 24.2 – 25 69

ALCR coating allows the user to operate at higher cutting speeds in materials that naturally generate an

excessive amount of heat during the milling process.