Page 101 - High Performance End Mills - Catalog 430

P. 101

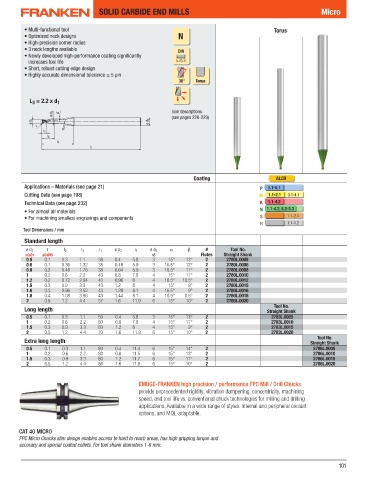

Applications – Materials (see page 21)

Cutting Data (see page 198)

Technical Data (see page 232)

Tool Dimensions / mm

ø d 1 r l 2 l 3 l 1 ø d 3 l 4 ø d 2

0.1 0.3 1.1 38 0.4 5.8 3 15° 13°

0.1 0.36 1.32 38 0.48 5.9 3 16.5° 12°

0.2 0.48 1.76 38 0.64 5.9 3 16.5° 11°

0.2 0.6 2.2 43 0.8 7.8 4 15° 11°

0.2 0.72 2.64 43 0.96 8 4 16.5° 10.5°

0.3 0.9 3.3 43 1.2 8 4 15° 9°

0.3 0.96 3.52 43 1.28 8.1 4 16.5° 9°

0.4 1.08 3.96 43 1.44 8.1 4 16.5° 8.5°

0.5 1.2 4.4 57 1.6 11.9 6 15° 10°

0.1 0.3 1.1 50 0.4 5.8 3 15° 13°

0.2 0.6 2.2 60 0.8 7.8 4 15° 11°

0.3 0.9 3.3 60 1.2 8 4 15° 9°

0.5 1.2 4.4 70 1.6 11.9 6 15° 10°

0.1 0.3 1.1 80 0.4 11.4 6 15° 14°

0.2 0.6 2.2 80 0.8 11.5 6 15° 13°

0.3 0.9 3.3 80 1.2 11.7 6 15° 11°

0.5 1.2 4.4 80 1.6 11.9 6 15° 10°

EMUGE-FRANKEN high precision / performance FPC Mill / Drill Chucks

provide unprecedented rigidity, vibration dampening, concentricity, machining

speed, and tool life vs. conventional chuck technologies for milling and drilling

applications. Available in a wide range of styles. Internal and peripheral coolant

options, and MQL-adaptable.

CAT 40 MICRO

FPC Micro Chucks slim design enables access to hard to reach areas, has high gripping torque and

accuracy and special coated collets. For tool shank diameters 1-6 mm.